Operations Research | Boosting the efficiency of wheel production at SKAD

Business case

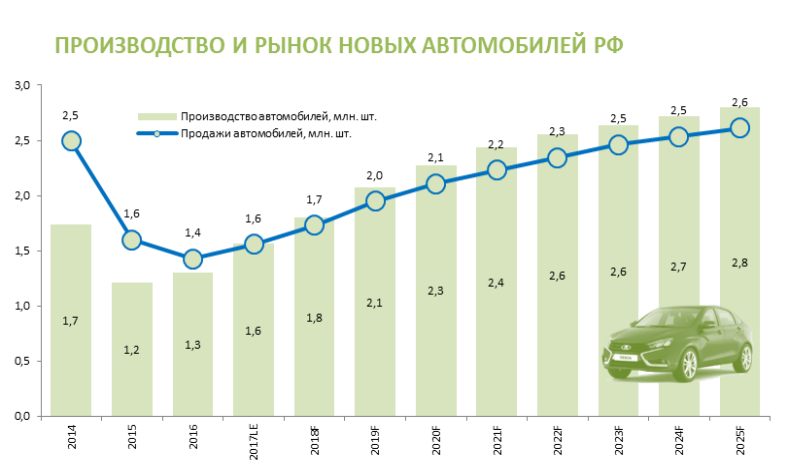

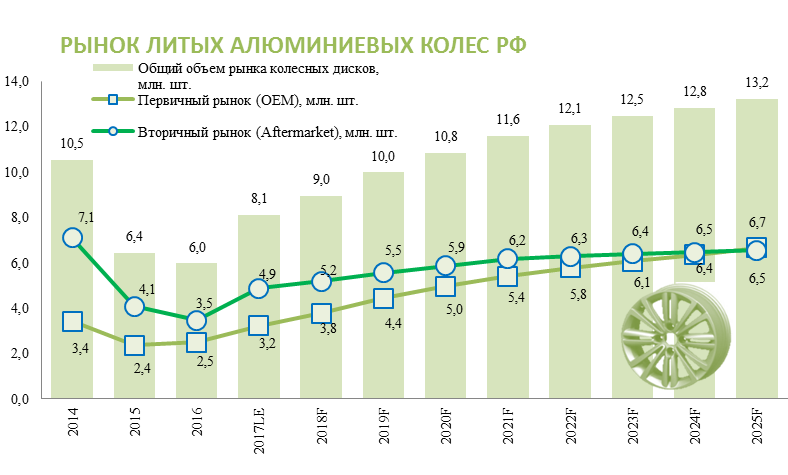

In 2018, the market of new cars continued to grow. The market volume for aluminium alloy wheels is about 8 mln units per year. According to current estimates, by 2025 the consumption of aluminium alloy wheels in Russia could increase by 44%, reaching over 13 mln units per year.

The current capacity of the Company allows it to meet less than 15% of the demand in Russia.

Goal:

Have a market share of at least 20%, even as demand continues to grow.

Development priorities:

Standardised work. Reduced fluctuations and increased load of the work centres.

Adopt TPM methods. Boosting overall equipment efficiency.

Sorting out quality issues using the 1*1 method Reducing in-house defects and production waste.

Current results:

Indicator |

UoM |

Before |

After |

Change |

Yield |

% |

81,3 |

85,2 |

+3,9 |

Production equipment downtime |

hours per month |

631,27 |

359,7 |

-43% |

Unscheduled equipment downtime |

hours per month |

623,41 |

455,1 |

-27% |

Market share |

% |

12 |

15 |

+3 |

Summary:

Operations improvements and elimination of waste allow the Company to boost output of aluminium alloy wheels by more than 90,000 units per year without having to retrofit the production equipment.