About | Info

The Aluminium alloy smelter produces a whole range of cast and wrought aluminium alloys in compliance with Russian GOST and international standards. Production capacity of the smelter is 80,000 tonnes of aluminium alloys per year.

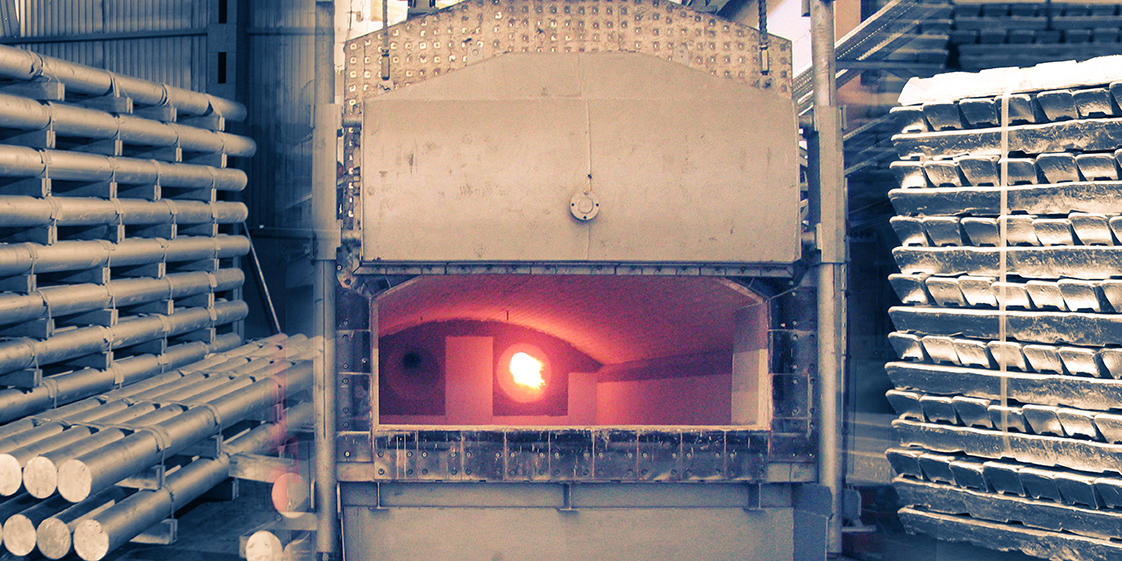

The production site of the smelter includes two smelting complexes, equipped with two kilns with a 40 tonnes capacity, four mixers with a 25-tonne capacity, as well as a tilting rotary kiln with a 25-tonne capacity.

The smelter’s laboratory has been certified by Gosstandard of Russia. The highly qualified specialists at the company work with modern analytical equipment to carry out metallurgic research to assess alloy structures, control hydrogen quantity, and define strength characteristics and properties of the alloys. The chemical composition of the alloys is determined using the ARL spectrometer.

In the production process, the liquid metal is exposed to many stages of development, degasification of inert gas, flux refining, and filtering using ceramic foam filters with 30-50 PPI. This ensures guaranteed quality in complex highly siliceous alloys.

A quality management system is in place at the smelter in compliance with ISO 9001:2008 series international standards, approved by certification of quality management system from the German Society for Quality ‘DQS’.

The company’s partners are leading consumers in Europe, the US, Japan, and countries around Asia, as well as Russian companies.

Official website: zasplav.ru

Contacts: Tel./fax: +74967605507

Location:142155, pr. Metallurgov, 3K, Podol'sk, Moskovskaya oblast'